vickers hardness test procedures|vickers hardness of common materials : member club How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad . Remastered - STEAMUNLOCKED » Free Steam Games Pr.

{plog:ftitle_list}

webBest Slots Best RTP Slots. New Slots Upcoming Slots Free Slots. Best Slots By Years. 2022 2023 2024. Best Slots By Casino Jackpot Slots. Online Casinos. . Section 8 .

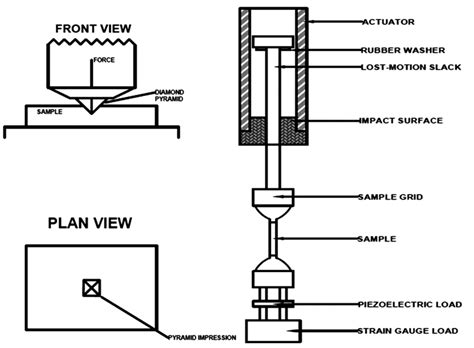

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 . Here’s the article for you to everything about Vickers hardness testing, including basics and principle, Vickers hardness test procedure, formula and calculation.The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .

How Does a Vickers Hardness Tester Work? 1. Preparation. 2. Application of Load. 3. Indentation. 4. Measurement. 5. Calculation. 6. Determination of Hardness. 7. Reporting. Advantages of Vickers Hardness Tester. 1. Broad .

Learn all you need to know about Vickers microhardness testing and microhardness testing machines – with knowledge, insight and troubleshooting tips from Struers, one of the world’s leading Vickers micro hardness tester . The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist .

Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation .Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three .

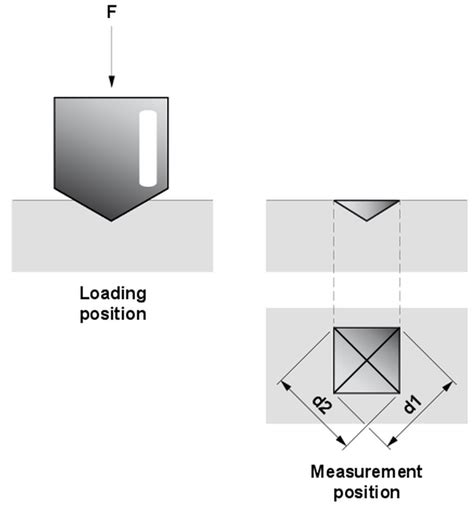

vickers hardness testing machine diagram

Vickers hardness testing is a preferred method for assessing the hardness of all types of metals, offering the most comprehensive range of hardness scale measurements .Hardness testing is a key element in many quality control procedures and R&D work. What is hardness testing? How can you select the best hardness testing method? . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must not . The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Further information regarding existing standards and procedures can be .

Figure: Vickers hardness test procedure. In the Vickers hardness test, a four-sided diamond pyramid is pressed into the material to be tested. The indentation surface left behind serves as a measure of the hardness value! The factor 0.102 again comes from the no longer used unit “kilopond” (see Brinell hardness test). The indentation .PRACTICAL HARDNESS TESTING MADE SIMPLE Table of Contents Page 1. GENERAL 1 2. INTRODUCTION 3 3. BRINELL HARDNESS TESTING 9 4. VICKERS HARDNESS TESTING 14 5. ROCKWELL HARDNESS TESTING 17 6. INFORMATIONS 22 i PRACTICAL HARDNESS TESTING MADE SIMPLE 1. GENERAL Important facts and features to be known and .The Vickers hardness test is a static hardness test method, used for both macro and microhardness testing. . The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Vickers methods.1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part B), and the calibration of standardized hardness test blocks (Part C). Two general classes of standard tests are recognized:

ASTM E92 describes the Vickers hardness test and Knoop hardness test using various test forces, ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf) and from 9.807 × 10-3 N to 19.613 N (1 gf to 2 kgf), respectively. For testing in the microindentation force range (forces ≤ 1 kgf), additional guidance and procedures can be found in . Basic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness de. The Vickers Hardness Test is one of four mainline procedures that will determine how suitable a material is for the purpose it is going to be used for. The procedure has a wide range of applications and is known to be effective in determining the strength and resistance of both metallic and non-metallic substances. 1.7 The test principles, testing procedures, and verification procedures are essentially identical for both the Vickers and Knoop hardness tests. The significant differences between the two tests are the geometries of the respective indenters, the method of calculation of the hardness numbers, and that Vickers hardness may be used at higher .

zwickroell.com . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-Consult operation instructions for specific maintaining and adjusting procedures. 2. Keep the tool clean for best results. 3. Remove adjusting tools and wrenches. Form habit of checking that adjusting tools . Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of . The Basics of Vickers Hardness Testing. Vickers Hardness Testing is based on a straightforward principle: the depth or size of an indentation left by an indenter in a material is directly proportional to the material's .GENERAL DESCRIPTION AND TEST PROCEDURE FOR VICKERS HARDNESS TESTS 4. Apparatus 4.1 Testing Machine—Equipment for Vickers hardness testing usually consists of a testing machine which supports the .

To ensure our progression in quality assurance, ATS’s Vickers Hardness Testing procedures abide by the ASTM E92 and ASTM E384 standards, for which we maintain ISO 17025 (A2LA) accreditation. With over 12,000 specifications developed by field experts, ASTM standards are internationally recognized, creating a basis of operations for service .

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the different types of ISO documents should be noted. . The Vickers hardness test is specified in this document for lengths of indentation .

I. Significance of Vickers Hardness Standard Test. Vickers hardness test is the nondestructive testing method, which is significant while evaluating materials, a quality check of the manufacturing procedure, and creating new products. Vickers hardness testing method is the only procedure that we can say is universal because of its scaling, as it can be used for .Vickers hardness testing, also called microhardness testing, is typically used for small parts, thin sections, or or case depth work. The Vickers method is based on an optical measurement system. The Microhardness testing procedure, ASTM E-384, specifies a series of light loads in which a diamond indenter makes an impression that is measured .The Vickers hardness test is specified in this part of ISO 6507 for lengths of indentation diagonals between 0,020 mm and 1,400 mm. . 7 Procedure 7.1 In general, the test is carried out at ambient temperature within the limits of 10 °C to 35 °C. Tests

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Vickers hardness testing to ASTM E92 is a hardness test method with optical evaluation in which the size of the indentation left on the surface of the test material by a pyramid-shaped diamond indenter (square base and interfacial angle of α = 136°) is measured. The test load is applied precisely and the diagonals of the indentations are used to calculate the Vickers .

The procedures used to develop this document and those intended for its further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the . ISO 6507-3, Metallic materials — Vickers hardness test — Part 3: Calibration of reference blocks 3 Terms and definitionsExplore the Vickers Hardness Test, its methodology, and applications in material science. Detailed guide available at Infinita Lab. . Procedure for Conducting the Vickers Hardness Test. To conduct a hardness test, the following steps are generally followed: Sample Preparation: The material sample should be smooth & flat. Surface preparation .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. + 86 755 61301520; [email protected]; Search.The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. This Vickers hardness test is usually easier to use compared to other hardness tests. The reason is the required calculations are not dependent on the size of the indenter. .

кондуктометрический влагомер

купить влагомер воздуха

webAssista vídeos pornô de Mulheres Transando de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta qualidade. .

vickers hardness test procedures|vickers hardness of common materials